The present article presents the main parts of the reciprocating internal combustion engine, which come under the scope of thermodynamics for the study of ideal power cycles of SI and CI engines.

Before we move to the proper definitions, it’s important to mention that the reciprocating engine is the most versatile invention in human history. It serves as a power bank for the vast majority of automobiles, aircraft, jet engines, electric generators, and so forth. For simplicity, here, we shall discuss only its piston-cylinder configuration with a few key terms.

Parts of The Reciprocating Internal Combustion Engine

Dead Centers

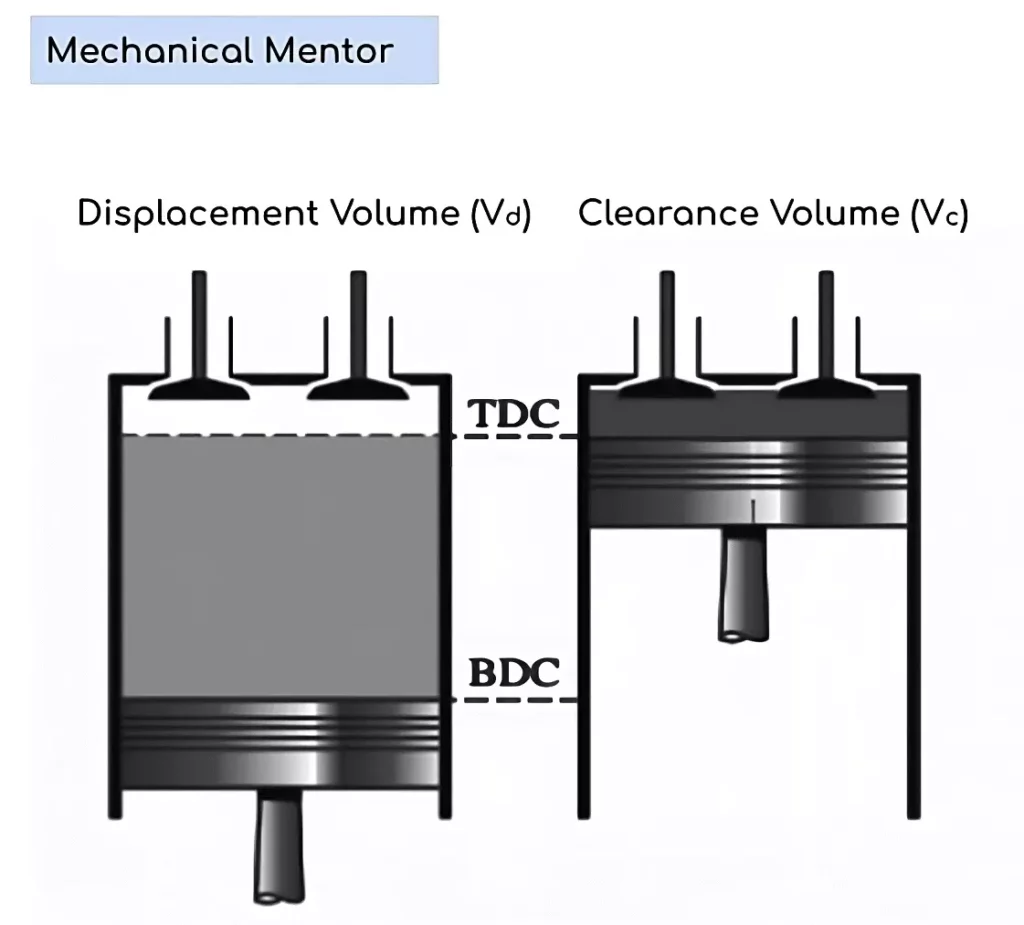

In the reciprocating engine, the piston moves between two fixed positions where the speed of the piston is zero, which is called its dead center. At dead centers, the piston changes its direction of motion.

Top Dead Center

It is the position of the piston when it forms the smallest volume in the cylinder. It is abbreviated as TDC. In the case of horizontal engines, this position is known as an inner dead center (IDC).

Bottom Dead Center

It is the position of the piston when it forms the largest volume in the cylinder. It is abbreviated as BDC. In the case of horizontal engines, this position is known as an outer dead center (ODC).

Stroke

It is the distance covered by the piston when it travels from the BDC position to that of the TDC or vice versa. In short, it is the largest possible distance in one direction which the piston covers. It is denoted by l and is equal to two times the radius of the crank.

l=2r

Bore

It is the diameter of the piston.

Intake Valve

The valve through which the combustible mixture, say air and petrol, enters the engine’s cylinder is called the intake valve.

Exhaust Valve

The valve through which the combustible gases are expelled from the engine’s cylinder is called the exhaust valve.

Clearance Volume

The minimum volume formed by the piston when it is at the top dead center is called the clearance volume. Vc, Vmin, or VTDC denote it.

Displacement Volume/Swept Volume

The maximum volume formed by the piston when it covers a distance equal to its single stroke is called the displacement volume. Vd Vmax or VBDC denotes it. It is also called the swept volume of the cylinder (Vd). Mathematically, it is given by stroke times the piston’s area.

V_d\;=l\;\times\;A_{piston}Cylinder Volume

It is the total volume of the cylinder. It is the volume between the bottom dead center and the cylinder head. Mathematically, it is the summation of clearance and swept volume.

V\;=\;V_c\;+\;V_d

Compression Ratio

It is the ratio of the total volume to the clearance volume of the cylinder. One can write the expression for compression ratio as follows:

r\;=\;\frac V{V_c}\;=\;\frac{V_c\;+\;V_d}{V_c}\;=\;1\;+\;\frac{V_d}{V_c}Mean Effective Pressure

It is a theoretical pressure, or as one would call the fictitious pressure, that, if acted on the piston during the whole expansion process or power stroke, would give the same network (Wnet) as that resulted during the actual cycle.

W_{net}\;=\;Mean\;Effective\;Pressure\;\times\;Displacement\;VolumeReordering the above equation gives:

M.E.P\;=\;\frac{W_{net}}{V_d}\;=\;\frac{W_{net}}{V-V_c}It is used to compare the performance of engines of equal size. The engine with a higher M.E.P delivers more net work per cycle than its counterpart with a lower M.E.P.

I am the author of Mechanical Mentor. Graduated in mechanical engineering from University of Engineering and Technology (UET), I currently hold a senior position in one of the largest manufacturers of home appliances in the country: Pak Elektron Limited (PEL).