The word robot has several definitions, some of which are general, whereas others are specific from the vantage of design and application.

In the early days of automation, or more precisely robotization, the Japanese defined the industrial robot as an all-purpose machine equipped with adequate memory and a structured mechanism for performing automatic motions as designed, thus replacing alienating human labor.

Definition

The present article will define industrial robots in reference to the two world-renowned automation associations.

- Japanese Industrial Robots Association (JIRA)

- Robot Institute of America (RI)

Japanese Industrial Robots Association (JIRA)

In the early periods of robots, the Japanese Industrial Robots Association (JIRA) Tokyo defined industrial robots by dividing them into six distinct categories as mentioned below:

Manual Manipulator

It is a robot simple in its operation. Unlike fully automatic robots (or manipulators), it works with human intervention in order to guide it in carrying out certain tasks. In simple words, the manual manipulator depends upon the robot operator for its controlled working throughout its operation. It is found in teleoperation scenarios in which a distant operator controls a robot.

Fixed Sequence Robot

It is a robot (or a manipulator) that executes successive steps of a given operation repeatedly in accordance with the pre-determined (or pre-decided) sets of instructions that include sequence, condition, and position. As its name implies, the set of information is fixed and cannot be easily changed.

Variable Sequence Robot

It is a robot (or a manipulator) that executes successive steps of a given operation repeatedly in accordance with the pre-determined (or pre-decided) sets of instructions that include sequence, condition, and position. As its name implies, the set of information can easily be changed.

Playback Robot

It is a robot (or a manipulator) that can reproduce from its memory the operations originally executed under human control. The robot operator first trains the robot in order to feed a set of instructions or memorize the information.

Thus, all the needful information related to the sequence, condition, and position is fed to the robot’s memory. Upon recalling these memorized instructions, now the robot can perform those actions automatically in a repeated manner by playing back the stored information.

NC Robot

It is a robot (or a manipulator) that acts to perform the designed tasks according to a sequence, condition, and position based on the numerical control (NC) data.

Like an NC machine, the NC manipulator uses software that includes punched tapes, cards, and digital switches. Its control mode is also similar to that of an NC machine.

Intelligent Robot

It’s a manipulator that is made intelligent in the sense that it is provided with the sensory perception, both visual and tactile, to detect changes in its environment and subsequently make its own decisions based on the given condition by working out of its intelligibility.

Robot Institute of America (RIA)

One popular yet very concise definition of an industrial robot is given by the Robot Institute of America (RIA). It states:

An industrial robot is a reprogrammable, multifunctional manipulator designed and constructed to move objects such as materials, tools, or special devices and equipment by acting upon variable programmed instructions in order to perform chosen industrial tasks automatically.

It is obvious from the precise reading of the above statement that the RI denies the first two definitions of the industrial robot by JIRA.

It is in agreement with the modern trends in industrial automation that require manipulators to be reprogrammed by rewriting the set of instructions.

In short, it can be observed that once we exclude manual manipulators and fixed sequence robots, all the remaining robots are basically a new modality (or a unique kind) of an NC machine as the control unit of an NC machine and that of a (reprogrammable) robot is virtually identical. Both share the same servomotor and the related drive circuitry. In discussing robots, we can easily refer them to the NC machines.

Why are industrial robots used?

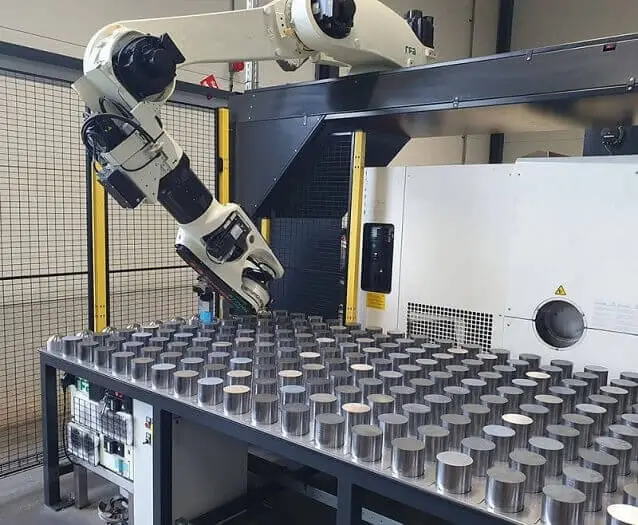

There are a number of reasons why robots are used in the industrial landscape. There is no such thing as a universal robot, as industries design robots keeping in view the maverick nature of their processes or other operational needs. It would be no unreasonable insight that the robots would decide the future course of modern factories.

Some of the reasons that lay behind the industrial use of robots are described below:

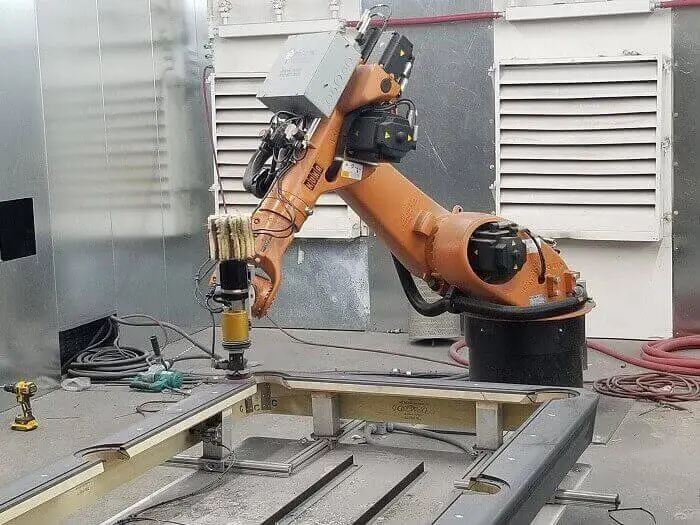

Hostile Environments

Historically speaking, the robots were developed to carry out operations in environments that were not human-friendly. Examples abound in the handling of radioactive or toxic materials, picking and releasing hot components (injection molded parts/extruded sheets), and so forth.

To comply with the guidelines stated by the Occupational Safety and Health Administration (OSHA), the primary purpose of using robots in industrial settings is to implicate robots where there is a danger to the operator’s health and safety.

Monotonous Jobs

The world witnessed a boom in the technologization of the mass production of commodities at the beginning of the twentieth century.

For instance, the cost of production of automobiles decreased immensely due to the unpacking of the agile and efficient ways of running assembly lines (thanks to Henry Ford).

However, this rapid growth in industrial production engrossed workers in activities that were dull, monotonous, and alienating.

To mitigate the likelihood of human alienation due to performing repetitive tasks that required only physical labor, such as tightening bolts on a pre-assembly stage uninterruptedly from morning to late afternoon, the robots were designed as an inevitable solution to this social impasse.

Even today, robots are being designed chiefly to perform those tasks that require no mental competence in terms of decision-making or critical thinking. To perform such duties, the robotization of manual labor offers a promising wayward to save humanity from anxiety and a deep sense of purposelessness.

Lifting Heavy Objects

Robots are also deemed indispensable in the industrial framework where there is a frequent need to lift heavy objects (for example, dead weights). Modern robots are sturdier in design and robust in construction. It can lift an object weighing more than half a ton.

Working in Odd Times

Robots can work indiscriminately at hours when human certainly feel reluctant to offer their services, such as in the evening and night shifts, on national holidays, and alike. Robots offer timeless service.

Increased Repeatability and Consistency

Humans cannot work with excellent repeatability as compared with their robot counterparts. Like an NC machine, a modern robot is capable of giving repeatability on the order of 0.002 inch (0.05mm) ensuring part quality and dimensional accuracy.

Frequently Asked Questions

What is an industrial robot?

According to the Robot Institute of America (RI), an industrial robot is a reprogrammable, multifunctional manipulator that can perform tasks related to moving materials, equipment, and devices by actualizing the variable programmed instructions in a repeated manner yet automatically.

What are the industrial robots used for?

They are intended to perform various tasks such as lifting heavy objects, picking hot molded parts from the machine, transferring extruded sheets to the thermoform cabinet’s mold in a thermoforming machine, moving finished products (industrial goods) from the final packaging line to the stack area, surgery, mining, weaponry and more importantly in environments where humans feel hesitant in doing work due to hostile workplace conditions.

Give one example of an industrial robot?

It is a cartesian robot used in 3D printing and with CNC machines.

I am the author of Mechanical Mentor. Graduated in mechanical engineering from University of Engineering and Technology (UET), I currently hold a senior position in one of the largest manufacturers of home appliances in the country: Pak Elektron Limited (PEL).