When the mating components are designed, the fit is a key concept that is kept in mind. From the perspective of the engineering design of the mating elements, such as a shaft and a hole, the fit is the measure of the looseness and tightness once a combination of allowances and tolerances are applied.

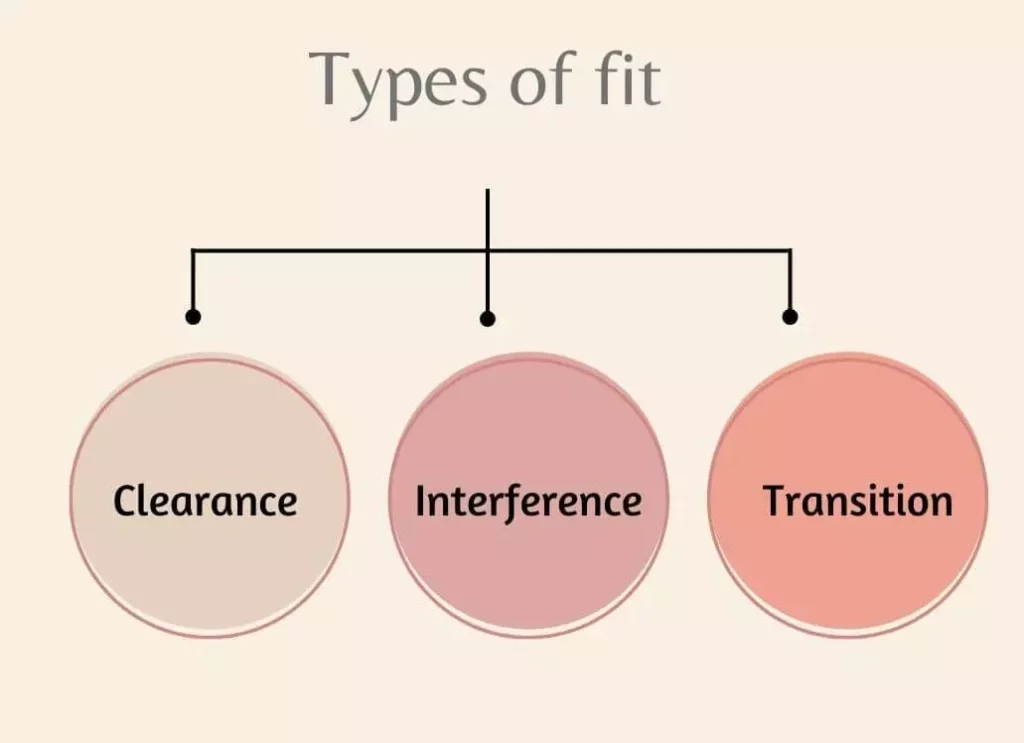

There are fundamentally three types of fits which are famously known as clearance, interference, and transition fit.

Types of Fit

- Clearance Fit

- Interference Fit

- Transition Fit

Clearance Fit

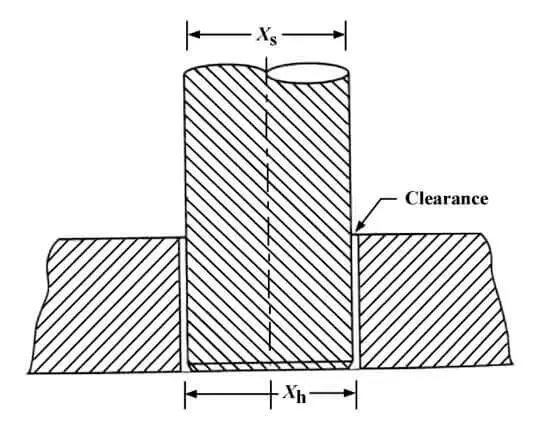

It is a type of fit in which clearance always results when the mating parts are assembled.

So, where is it used? It is used in the accurate assembly of parts and bearings. The two mating components or parts are assembled by hand as the size of the hole (Xh) is larger than that of the shaft (Xs).

In the figure shown below, a clearance fit between the shaft and bearing is manifested. It shows that after the tolerances on both shaft and bearing are maintained, the size of the bearing hole would always be larger than the shaft.

There are further different types of clearance fit based on their applications as follows:

- Sliding Fit: It is a clearance fit that exists between the mating parts that slide relative to each other. Examples include drawers and machinery parts.

- Running Fit: It is a clearance fit that exists between the mating parts that rotate relative to each other. Examples include a shaft rotating in a bearing.

- Slip Fit: It is a form of clearance fit for the assembly and disassembly of the mating parts without force.

- Location Fit: It is a clearance fit that exists between the mating parts in order to give proper alignment to both.

- Thermal Clearance fit: Where there are thermal changes due to temperature variance such as expansion and contraction, a clearance fit is given between the mating parts to accommodate such effects without interference.

- Piston and Cylinder Fit: There exists between the engine piston and cylinder a clearance fit for sliding movement as well as proper lubrication.

- Nut and Bolt Fit: A clearance fit is provided between a nut and bolt so that a nut can be threaded onto the bolt without much labor.

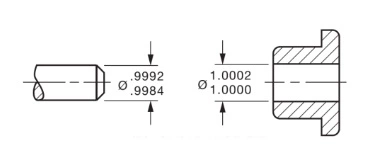

Interference Fit/Force Fit

It is a type of fit in which interference always results between the two mating parts when they are assembled. The limits of size are prescribed thus that the size of the hole is smaller than that of the shaft. Where is the application of such fits? It is used in permanent assemblies such as dowel pins and bearings in castings which require both rigidity and almost perfect alignment.

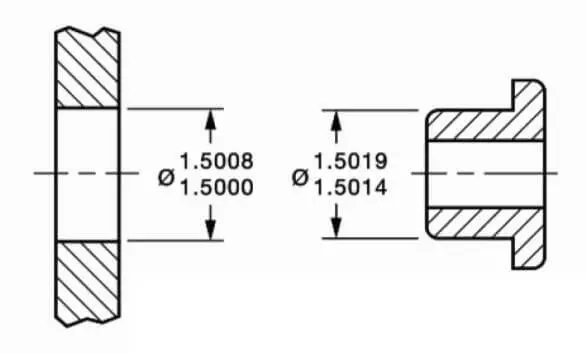

When an interference fit is designed between the mating parts, they are generally preseed together using an arbor press. In the figure below, an interference fit is shown, for instance, between the shaft and bearing. Once tolerances are maintained on each part, the size of the shaft would be larger than the hole.

There are further different types of interference fit based on their applications as follows:

- Press Fit: The mating parts are fully tightened and secured in place by getting pressed. Its examples include those in the aerospace, automobile, and manufacturing industries.

- Shrink Fit: Prior to fitting, the shaft is cooled in order to contract its metal. It is now inserted into the hole where it is heated and expanded thereby making a shrink fit. It is used in high-precision assemblies such as spindle tool spindles.

- Force Fit: This fit is achieved by hydraulic or mechanical means. The mating parts are assembled under mammoth force. Examples include heavy machinery and construction equipment.

- Gear and Spline Fit: Gears/splines make an interference fit with the mounting shaft through mechanical keys in keyways in order to secure their position firmly. Another example is bushing or bearing on a shaft.

- Crankshaft and Engine Block Fit: There exists between the engine block and crankshaft an interference fit for sealing the mating area in order to assist the combustion process.

Transition Fit

It is a type of fit in which when the mating parts are assembled, either a clearance or an interference fit would result. Thus, one says, it’s an engineering compromise between clearance and interference fits.

It is used in applications where accurate locations are needed yet where clearance or interference between the shaft and bearing is permissible.

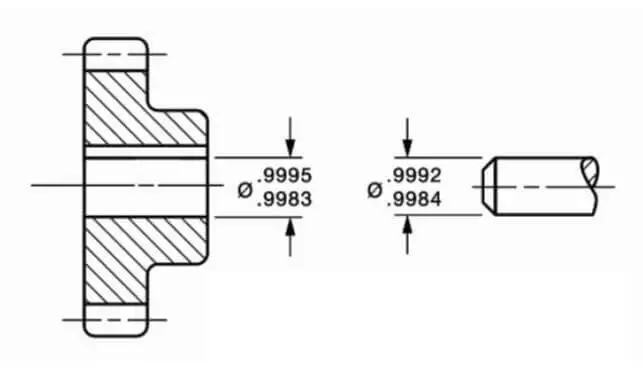

The figure shown above shows two such possibilities: when the hole of the gear is machined such that the size of the hole is larger than the shaft, a clearance fit would result. In case, if the size of the gear hole is smaller than that of the shift, it would result in the interference fit.

There are further different types of interference fit based on their applications as follows:

- Tapered Fit: It is provided in applications in which a tapered surface such as a taper pin is to be fitted into a hole. In such a case, either an interference or a clearance fit is chosen or both at the same time depending upon the desired fit characteristics.

- Taper Roller Bearing: It is provided with the transition fit: clearance fit for smooth rotation of the shaft and interference fit for enhanced load bearing capacity.

- Machine Tool Slides: In precision tooling, the machine tool slide and the guideways are transition-fitted in order to ensure perfect alignment and mobility as well as metal thermal expansion or contraction.

- Cylindrical Pins and Holes: Cylindrical holes make transitions fit with the holes to result in adequate alignment and ease of disassembly.

- Electrical/Electronic Parts: Electrical components such as co-axial connectors are provided with the transition fit in order to result in electrical continuity yet with the ease of its insertion and removal.

Finally, all these types of fits (clearance, interference and transition) can be created in the mating parts using classic machine tools such as lathe, milling machine, drill press, planer, among others. For example, lathe operations are used for achieving interference fits in shafts and bearings. Milling processes are apt to get interference and tight fits in press-fitted components like pulleys and gears. Drill presses are put to machining for drilling holes where bolts and screws are to be fit with least resistance (clearance fit). Grinders are preferred to produce tight tolerances and interference fits in parts that require high precision. Shapers are nuanced for cutting flat surfaces with needful clearance fit to provide enough DOF. Lastly, broaching machines are intended to machine keyways/splines thus ensuring interference fits for parts like keys and gears.

I am the author of Mechanical Mentor. Graduated in mechanical engineering from University of Engineering and Technology (UET), I currently hold a senior position in one of the largest manufacturers of home appliances in the country: Pak Elektron Limited (PEL).